Page 589 - scvhs19901997minutes

P. 589

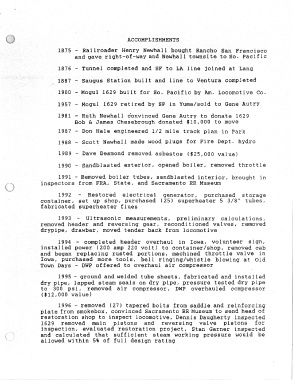

ACCOMPLISHMENTS

1875 - Railroader Henry Newhall bought Rancho San Francisco

and gave right-of-way and Newhall townsite to So. Pacific

1876 - Tunnel completed and SF to LA line joined at Lang

1887 - Saugus Station built and line to Ventura completed

1900 - Mogul 1629 built for So. Pacific by Am. Locomotive Co.

1957 - Mogul 1629 retired by SP in Yuma/sold to Gene Autry

1981 - Ruth Newhall convinced Gene Autry to donate 1629

Bob & James Chesebrough donated $10,000 to move

C

1987 - Don Hale engineered 1/2 mile track plan in Park

1988 - Scott Newhall made wood plugs for Fire Dept. hydro

1989 - Dave Desmond removed asbestos {$25,000 value)

1990 - sandblasted exterior, opened boiler, removed throttle

1991 - Removed boiler tubes, sandblasted interior, brought in

inspectors from FRA, State, and Sacramento RR Museum

0

1992 - Restored electrical generator, purchased storage

container, set up shop, purchased (25) superheater 5 3/8" tubes,

fabricated superheater flues

1993 - Ultrasonic measurements, preliminary calculations,

removed header and reversing gear, reconditioned valves, removed

drypipe, drawbar, moved tender back from locomotive

1994 - completed header overhaul in Iowa, volunteer sign,

installed power (200 amp 220 volt) to container/shop, removed cab

and began replacing rusted portions, machined throttle valve in

Iowa, purchased more tools, bell ringing/whistle blowing at Old

Town Days - DWP offered to overhaul air compressor

1995 - ground and welded tube sheets, fabricated and installed

dry pipe, lapped steam seals on dry pipe, pressure tested dry pipe

to· 300 psi, removed air compressor, DWP overhauled compressor

($12,000 value) ·

1996 - removed (27) tapered bolts from saddle and reinforcing

plate from smokebox, convinced Sacramento RRMuseum·to send head of

restoration shop to inspect locomotive, Dennis Daugherty inspected

1629 removed main pistons and reversing valve pistons for

inspection, evaluated restoration project, Stan Garner inspected

( -) and calculated that sufficient steam working pressure would be

)

allowed within 5% of full design rating